Product description

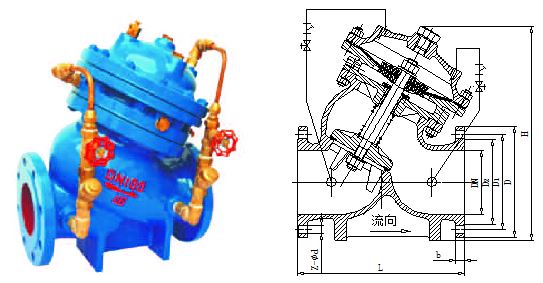

Multifunctional pump control valve from the main valve and control valve and take over the system components, body with DC type valve, the main valve control room for diaphragm or piston type dual structure of the control room, control room than ordinary hydraulic control valve to increase a, an increase of the main valve control function, realized on the pump outlet opened slowly, full, slow closing, closing and other multi-function control, realized a valve, a regulation on the pump outlet multi-function control.

working principle:

When the pump starts, the water pressure acting on the main valve disc below and control room, the pressure to open the main valve, control room on the water through the cavity B slowly discharged to the outlet end, the main valve slowly open. Setting the opening of the regulating valve can be suitable for the opening speed of the landlord valve. When the water pump stops working, the inlet pressure decreased rapidly, in weight, spring pressure quickly shut down most of the opening, to prevent the backflow of water remaining open degree by controlling chamber cavity pressure and water pressure of the lower cavity under the combined action of slowly closed, closing speed slow down the formation of the buffer, to prevent the pressure surge.

Main connection and outline dimensions(PN10)

nominal diameter

Main connection and outline dimensions(mm)

valve size mm

flange connection size mm

L

H

D

D1

D2

b

f

Z-Φd

50

203

293

165

125

93

18

3

4-Φ18

65

215

328

185

145

113

18

3

4-Φ18

80

248

364

200

160

128

20

3

8-Φ18

100

283

418

220

180

148

20

3

8-Φ18

125

330

481

250

210

178

22

3

8-Φ18

150

356

543

285

240

204

22

3

8-Φ22

200

444

673

340

295

259

24

3

8-Φ22

250

533

792

395

350

314

26

3

12-Φ22

300

600

927

445

400

362

26

4

12-Φ22

350

622

957

505

460

422

26

4

16-Φ22

400

698

1188

565

515

473

26

4

16-Φ26

450

775

1218

615

565

523

28

4

20-Φ26

Main connection and outline dimensions(PN16)

nominal diameter

Main connection and outline dimensions(mm)

valve size mm

flange connection size mm

L

H1

D

D1

D2

b

f

Z-Φd

50

203

293

165

125

93

18

3

4-Φ18

65

215

328

185

145

113

18

3

4-Φ18

80

248

364

200

160

128

20

3

8-Φ18

100

283

418

220

180

148

20

3

8-Φ18

125

330

481

250

210

178

22

3

8-Φ18

150

356

543

285

240

204

22

3

8-Φ22

200

444

673

340

295

259

24

3

12-Φ22

250

533

792

405

355

315

26

3

12-Φ26

300

600

927

460

410

370

28

3

12-Φ26

350

622

957

520

470

428

30

4

16-Φ26

400

698

1188

580

525

479

32

4

16-Φ30

450

775

1218

640

585

539

40

4

20-Φ30

Main parts material

Material code

Valve body, valve cover

The stem

valve seat

Sealing ring

the diaphragm

Spring

Z

HT200 gray cast iron

20Cr13

Gray cast iron

NR/NBR/EPDM/FEP/PFA

NR/NBR/EPDM/FEP/PFA

stainless steel

Q

QT450 nodular cast iron

20Cr13

nodular cast iron

C

WCB carbon steel

20Cr13

carbon steel

Other special materials, our company can also be tailored to customer needs.

Shell material

Shell applicable temperature(℃)

Housing applicable pressure MPa

Gray cast iron(Z type)

≤200

≤1.6

Nodular graphite cast iron(Q type)

≤350

≤4.0

Carbon steel(C type)

≤425

-

Sealing ring / diaphragm

Applicable medium

Applicable temperature(℃)

Natural rubber(NR)

hydrochloric acid, 30% sulfuric acid, 50% hydrofluoric acid, alkali, etc. 50%30% hydrochloric acid, sulfuric acid, hydrofluoric acid, alkali, etc.

≤85

Nitrile rubber (NBR)

Water, oil, waste gas and waste liquid pollution, etc.

≤150

Ethylene propylene rubber (FPDM)

In addition to salt water, 40% boron water, 5%~15% nitric acid and sodium hydroxide, etc..

≤120

Poly (ethylene propylene) plastics(FEP)

In addition to the molten alkali metals, fluorine and aromatic hydrocarbons hydrochloric acid, sulfuric acid, aqua regia, organic acid, strong oxidizing agents, concentrated and dilute acid alternate, alternating alkaline and various organic solvents

≤150

Fusible polytetrafluoroethylene(PFA)

≤180

Nominal pressure PN(MPa)

shell(MPa)

Test pressure(MPa)

Seal (liquid)

Seal (gas)

1.0

1.5

1.1

0.6

1.6

2.4

1.76

0.6

- Implementation standards

Design specification: JB/T10674

Structure length: JB/T10674, GB/T 12221

Connecting flange: GB/T9113, HG/T20592, HG/T20615, JB/T 79

Experiment and test: GB/T13927, JB/T 9092

Pressure temperature: GB/T 17241.7, GB/T12224

Product identification: GB/T 12220

- Valve maintenance

(1) the engineering application of the hydraulic control valve is a manufacturing plant inspection, a variety of complete, technical information to meet the requirements of the product.

(2) the nominal pressure of the valve has different levels, the pipeline transportation of the media, the working pressure should be less than the value of the valve nominal pressure.

(3) the project of the hydraulic control valve setting should have enough space for management, operation, installation and maintenance, and should meet the requirements of the pipeline valve.

(4) when the pipe is connected by flange, the hydraulic control valve with flange connection should be adopted, and the hydraulic control valve with groove connection should be adopted when the pipeline is connected with a groove.

(5) the hydraulic control valve should be set on the one-way flow of media in the pipeline.

(6) the direction of the arrow on the main body of the hydraulic control valve must be consistent with the direction of the pipeline system.

(7) the water control valve should not have gas blocking, air resistance. Automatic exhaust valve should be set at the highest position of the pipe network.

(8) when the valve is installed, the valve cover and valve stem should be facing up. Vertical installation, valve cover, valve stem should be outward.

(9) the valve should be done before the installation of strength and tightness test.

More Products