Product description

100D water valve is a valve diaphragm type adjustment tank and water tower in height. The valve is controlled by the floating ball, when the liquid level reaches the set height, the valve passes the signal through the relevant structure to transfer a water pump, and the water pump stops the water supply; when the liquid level bottom is in the set position, the water pump automatically supply water. The valve action is stable and effective to prevent the opening of the pump water hammer and stop pump water hammer. Avoid excessive pressure on the pipe. Automatic water supply system for water tank, a water tower. The valve maintenance is simple, flexible and durable, high accuracy of level control, the water level is not affected by water pressure interference and close tight, reliable performance.

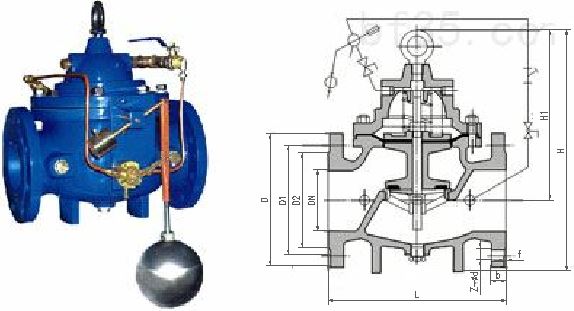

Main connection and dimensions(PN10)

公称

通径

主要外形尺寸及连接尺寸(mm)

阀门尺寸mm

法兰连接尺寸mm

L

H1

H

D

D1

D2

b

f

Z-Φd

50

203

210

265

165

125

93

18

3

4-Φ18

65

213

215

310

185

145

113

18

3

4-Φ18

80

241

245

350

200

160

128

20

3

8-Φ18

100

272

305

460

220

180

148

20

3

8-Φ18

125

300

365

520

250

210

178

22

3

8-Φ18

150

333

415

570

285

240

204

22

3

8-Φ22

200

400

510

595

340

295

259

24

3

8-Φ22

250

480

560

780

395

350

314

26

3

12-Φ22

300

550

658

905

445

400

362

26

4

12-Φ22

350

620

696

1025

505

460

422

26

4

16-Φ22

400

685

735

1030

565

515

473

26

4

16-Φ26

450

750

610

1080

615

565

523

28

4

20-Φ26

500

810

665

1135

670

620

578

28

4

20-Φ26

600

935

725

1270

780

725

677

34

5

20-Φ30

主要连接及外形尺寸(PN16)

公称

通径

主要外形尺寸及连接尺寸(mm)

阀门尺寸mm

法兰连接尺寸mm

L

H1

H

D

D1

D2

b

f

Z-Φd

50

203

210

265

165

125

93

18

3

4-Φ18

65

213

215

310

185

145

113

18

3

4-Φ18

80

241

245

350

200

160

128

20

3

8-Φ18

100

272

305

460

220

180

148

20

3

8-Φ18

125

300

365

520

250

210

178

22

3

8-Φ18

150

333

415

570

285

240

204

22

3

8-Φ22

200

400

510

595

340

295

259

24

3

12-Φ22

250

480

560

780

405

355

315

26

3

12-Φ26

300

550

658

905

460

410

370

28

3

12-Φ26

350

620

696

1025

520

470

428

30

4

16-Φ26

400

685

735

1030

580

525

479

32

4

16-Φ30

450

750

610

1080

640

585

539

40

4

20-Φ30

500

810

665

1135

715

650

601

44

4

20-Φ33

600

935

725

1270

840

770

716

54

5

20-Φ36

主要连接及外形尺寸(PN25)

公称

通径

主要外形尺寸及连接尺寸(mm)

阀门尺寸mm

法兰连接尺寸mm

L

H

H1

D

D1

D2

b

f

Z-Φd

50

203

210

265

165

125

93

20

3

4-Φ18

65

213

215

310

185

145

113

22

3

8-Φ18

80

241

245

350

200

160

128

24

3

8-Φ18

100

272

305

460

235

190

154

24

3

8-Φ22

125

300

365

520

270

220

180

26

3

8-Φ26

150

333

415

570

300

250

210

28

3

8-Φ26

200

400

510

595

360

310

270

30

3

12-Φ26

250

480

560

780

425

370

326

32

3

12-Φ30

300

550

658

905

485

430

386

34

3

16-Φ30

350

620

696

1025

555

490

441

38

4

16-Φ33

400

685

735

1030

620

550

498

40

4

16-Φ36

450

750

610

1080

670

600

548

46

4

20-Φ36

500

810

665

1135

730

660

608

48

4

20-Φ36

600

935

725

1270

845

770

713

58

5

20-Φ39

Main parts material

Material code

Valve body, valve cover

The stem

valve seat

sealing ring

diaphragm

spring

Z

HT200 Gray cast iron

20Cr13

Gray cast iron

NR/NBR/EPDM/FEP/PFA

NR/NBR/EPDM/FEP/PFA

stainless steel

Q

QT450 Nodular graphite cast iron

20Cr13

Nodular graphite cast iron

C

WCB carbon steel

20Cr13

carbon steel

Other special materials, our company can also be tailored to customer needs.

Main performance characteristics

Shell material

Shell applicable temperature(℃)

Casing applicable pressure MPa

Gray cast iron(Z type)

≤200

≤1.6

Nodular graphite cast iron(Q type)

≤350

≤4.0

carbon steel(C type)

≤425

-

stainless steel(R type)

≤650

-

Sealing ring / diaphragm

Applicable medium

Applicable temperature(℃)

Natural rubber (NR)

ydrochloric acid, 30% sulfuric acid, 50% hydrofluoric acid, alkali, etc. 50%

≤85

Nitrile rubber(NBR)

Water, oil, waste gas and waste liquid pollution.

≤150

Ethylene propylene rubber (FPDM)

In addition to salt water, 40% boron water, 5%~15% nitric acid and sodium hydroxide, etc..

≤120

Poly (ethylene propylene) plastics(FEP)

In addition to the molten alkali metals, fluorine and aromatic hydrocarbons hydrochloric acid, sulfuric acid, aqua regia, organic acid, strong oxidizing agents, concentrated and dilute acid alternate, alternating alkaline and various organic solvents.

≤150

Fusible polytetrafluoroethylene (PFA)

≤180

Nominal pressure PN(MPa)

Shell(MPa)

Test pressure(MPa)

Seal (liquid)

Seal (gas)

1.0

1.5

1.1

0.6

1.6

2.4

1.76

0.6

2.5

3.75

2.75

0.6

- Implementation standards

Design specification: JB/T10674

Structure length: JB/T10674, GB/T 12221

Connecting flange: GB/T9113, HG/T20592, HG/T20615, JB/T 79

Experiment and test: GB/T13927, JB/T 9092

Pressure temperature: GB/T 17241.7, GB/T12224

Product identification: GB/T 12220

- Valve maintenance

(1) the engineering application of the hydraulic control valve is a manufacturing plant inspection, a variety of complete, technical information to meet the requirements of the product.

(2) the nominal pressure of the valve has different levels, the pipeline transportation of the media, the working pressure should be less than the value of the valve nominal pressure.

(3) the project of the hydraulic control valve setting should have enough space for management, operation, installation and maintenance, and should meet the requirements of the pipeline valve.

(4) when the pipe is connected by flange, the hydraulic control valve with flange connection should be adopted, and the hydraulic control valve with groove connection should be adopted when the pipeline is connected with a groove.

(5) the hydraulic control valve should be set on the one-way flow of media in the pipeline.

(6) the direction of the arrow on the main body of the hydraulic control valve must be consistent with the direction of the pipeline system.

(7) the water control valve should not have gas blocking, air resistance. Automatic exhaust valve should be set at the highest position of the pipe network.

(8) when the valve is installed, the valve cover and valve stem should be facing up. Vertical installation, valve cover, valve stem should be outward.

(9) the valve should be done before the installation of strength and tightness test.

More Products