The product description

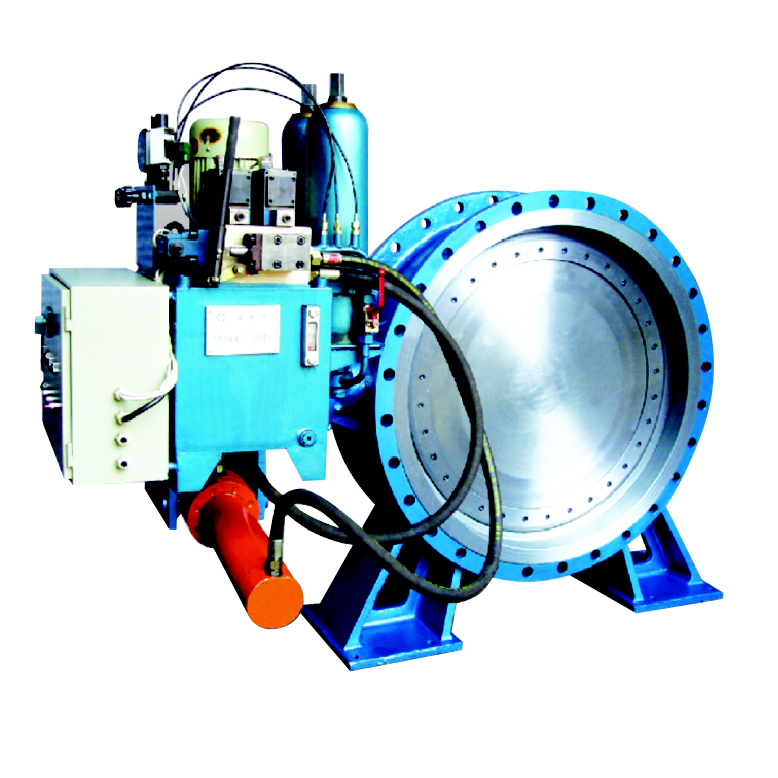

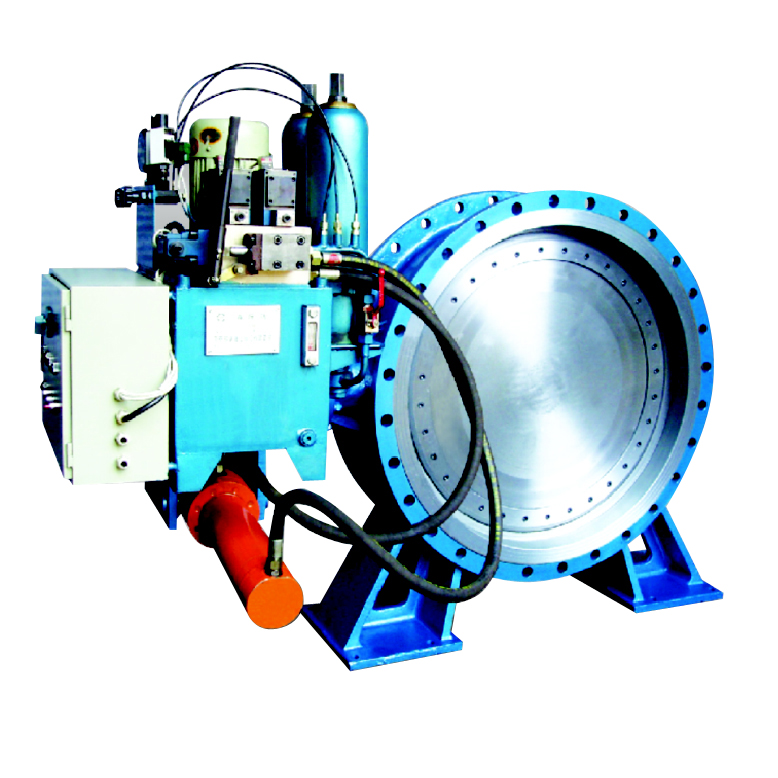

Energy storage tank type hydraulic control slow close check butterfly valve is our factory in digesting and absorbing foreign hydraulic control valve based on the latest development of new products. At present, the valve is the latest generation of hydraulic control butterfly valve in our country, it has both the function of the gate valve and check valve, is a kind of can according to the setting in advance good program, two stages (fast clearance Angle, and then slowly closed rest Angle) closed action to eliminate water hammer in pipeline damage their ideal control system.

Structural characteristics of

This product is mainly composed of butterfly valve body, transmission device, hydraulic and electrical control part of the group. Has the following main features:

A. environmental protection products in the valve cavity through the water using harmless to human body health and safety and environmentally friendly coatings, in drinking water sanitation standard, the medium in pipeline doesn't create any pollution.

B. conventional type product in the valve cavity through the water the adhesion of anticorrosion coatings. This valve seal form is divided into two kinds, the first form is: stainless steel, stainless steel, and USES the three eccentric structure of its sealing performance and reliable butterfly plate shut tight, easy to release; Seal adopt stainless steel, corrosion resistant wear long service life, convenient maintenance, after the valve with long steel rubber, it USES a leak, only need to replace the sealing ring; Bearing for lead-free no oil self-lubricating bearing has a carrying capacity is strong, good wear resistance, low friction resistance and other characteristics; Shaft end seal USES self-tightening type such as double seal, the sealing effect is good. Butterfly plate plastic adopts streamline design, small flow resistance coefficient (< 0.2), the valve strength, good rigidity, body strength test can withstand twice the nominal pressure. Has the characteristics of novelty, beautiful shape.

This valve has a perfect hydraulic system and electric control system, as well as on-site operation, also can remote operation, but this valve control system USES the storage tank to replace the present domestic several valve factory in the production of hydraulic control butterfly valve with a heavy hammer hammer, hammer potential energy into hydraulic energy, not only save the long running bearing weight of energy consumption, improved the hydraulic pressure performance of the system to avoid the runtime maintenance personnel casualty accidents and mental insecurity and fear, and its control mechanism design is novel, reasonable design, small volume, light weight, simple structure, complete functions, movements flexible and reliable, beautiful appearance, energy saving material, convenient maintenance, and do not need to stop the pump when maintenance work and so on. To easily realize pump valve interlocking program control and microcomputer centralized control, power failure, shaking the manual oil pump can close the valve. The valve open and close, the movement is very convenient. This valve hydraulic and electric control parts be separated from the valve installed, according to whether the hydraulic and electrical separation and two kinds of forms, user can choose according to the situation.

The working principle of

Hydraulic system power supply electrical units, there are three kinds of oil pump accumulator hydraulic energy storage, manual oil pump, which stored in accumulator hydraulic can give priority to power supply, pump unit is responsible for the accumulator charging, when need can also direct drive valve switch, manual oil pump used in the accumulator, in the absence of any stored energy without electricity manual switch valve. To lose electric valve type hydraulic system, the two solenoid valve electromagnet to when the valve opens at the same time, the loss of electricity at the same time the valve closed. For electric valve type hydraulic system, an electromagnetic valve electromagnet electric valve opens, the other electromagnetic valve electromagnet closed electric valve. Open valve speed regulation by integrated block throttle valve; In two stages, automatically shut off the valve closed fast first is about 65 ℃, and then slowly closed left about 25 ℃, fast closing speed and Angle in the cylinder backend device regulation. In the case of without electricity or need to manually, by artificial push electromagnetic valve valve core, make the oil in the corresponding state, shaking the manual oil pump, can open or close the valve.

The main connection and shape size

nominal size

The main valve connection size mm

valve connection size mm

flange connection size mm

DN

L

H

H1

H2

H3

H4

H5

H6

L1~L5

n-d

A1

A2

D

K

D0

b

N-Φ

300

178

310

575

285

220

670

540

816

According to the

The guest

households

650

1200

440

395

363

24

12-23

350

190

320

605

317

220

670

540

816

650

1200

490

445

413

26

12-23

400

216

340

640

345

220

720

540

912

700

1400

540

495

463

28

16-23

450

222

370

670

373

220

720

540

912

700

1400

595

550

518

28

16-23

500

229

400

735

400

240

720

540

912

700

1400

645

600

568

30

20-23

600

267

460

800

459

240

720

610

912

700

1400

755

705

667

30

20-26

700

292

540

856

520

240

825

610

1095

800

1600

860

810

772

32

24-26

800

318

580

990

578

310

825

610

1095

800

1600

975

920

878

34

24-31

900

330

635

1039

655

310

825

610

1095

800

1600

1075

1020

978

36

24-31

1000

410

695

1089

718

310

825

610

1095

800

1600

1175

1120

1078

36

28-31

1200

470

810

1219

845

310

825

610

1095

800

1600

1375

1320

1280

30

32-30

1400

530

920

1329

975

360

855

610

1329

800

1800

1575

1520

1480

30

36-30

1600

600

1040

1479

1100

360

855

610

1329

800

1800

1790

1730

1690

32

40-30

1800

670

1140

1650

1240

360

855

610

1329

800

1800

1990

1930

1890

34

44-30

2000

760

1250

1800

1359

525

895

810

1234

900

1800

2190

2130

2090

34

48-30

2200

590

1360

1979

1500

525

940

810

1234

900

1800

2405

2340

2295

36

52-33

The main connection and shape size PN6

主要阀门连接尺寸mm

阀门连接尺寸mm

法兰连接尺寸mm

DN

L

H

H1

H2

H3

H4

H5

H6

L1~L5

n-d

A1

A2

D

K

D0

b

N-Φ

300

178

310

575

285

220

670

540

816

根

据

客

户

需

求

定

做

650

1200

440

395

363

24

12-23

350

190

320

605

317

220

670

540

816

650

1200

490

445

413

26

12-23

400

216

340

640

345

220

720

540

912

700

1400

540

495

463

28

16-23

450

222

370

670

373

220

720

540

912

700

1400

595

550

518

28

16-23

500

229

400

735

400

240

720

540

912

700

1400

645

600

568

30

20-23

600

267

460

800

459

240

720

540

912

700

1400

755

705

667

30

20-26

700

292

540

856

520

240

825

610

1095

800

1600

860

810

772

32

24-26

800

318

580

991

578

310

825

610

1095

800

1600

975

920

878

34

24-31

900

330

635

1039

655

310

825

610

1095

800

1600

1075

1020

978

36

24-31

1000

410

695

1089

718

310

825

610

1095

800

1600

1175

1120

1078

36

28-31

1200

470

810

1239

845

360

855

610

1329

800

1800

1405

1340

1295

40

32-34

1400

530

920

1359

975

360

855

610

1329

800

1800

1630

1560

1510

44

36-37

1600

600

1040

1513

1100

525

895

810

1234

900

1800

1830

1760

1710

48

40-37

1800

670

1140

1655

1240

525

895

810

1234

900

1800

2045

1970

1918

50

44-40

2000

760

1250

1843

1359

680

895

810

1234

900

1800

2265

2180

2125

54

48-43

主要连接及外形尺寸PN10

公称

通径

主要阀门连接尺寸mm

阀门连接尺寸mm

法兰连接尺寸mm

DN

L

H

H1

H2

H3

H4

H5

H6

L1~L5

n-d

A1

A2

D

K

D0

b

N-Φ

300

178

310

630

285

220

670

540

816

根

据

客

户

需

求

定

做

650

1200

445

400

370

28

12-23

350

190

320

643

317

220

670

540

816

650

1200

505

460

429

30

16-23

400

216

340

660

345

240

720

540

912

700

1400

565

515

480

32

16-28

450

222

370

710

380

240

720

540

912

700

1400

615

565

530

32

20-28

500

229

400

720

425

240

720

540

912

700

1400

670

620

582

34

20-28

600

267

460

795

469

240

720

540

912

700

1400

780

725

682

36

20-31

700

292

540

910

530

310

825

610

1095

800

1600

895

840

794

40

24-31

800

318

580

980

590

310

825

610

1095

800

1600

1015

950

901

44

24-34

900

330

635

1050

665

310

825

610

1095

800

1600

1115

1050

1001

46

28-34

1000

410

695

1107

718

360

895

610

1329

800

1600

1230

1160

1112

50

28-37

1200

470

810

1150

855

360

895

610

1329

800

1600

1455

1380

1328

56

32-40

1400

530

920

1413

1000

525

940

810

1234

900

1800

1675

1590

1530

62

36-43

1600

600

1040

1618

1130

680

940

810

1234

900

1800

1915

1820

1750

68

40-49

1800

670

1140

1758

1250

680

940

810

1234

900

1800

2115

2020

1950

70

44-49

2000

760

1250

1960

1359

680

940

810

1234

900

1800

2325

2230

2150

74

48-49

-

Main parts material

material code

Valve body, valve cover, valve plate

valve seat

sealing ring

valve stem

filler

Q

QT450 Nodular graphite cast iron

Q450+Copper / stainless steel

Stainless steel multi layer / rubber

20Cr13

graphite

C

WCB carbon steel

WCB+Copper / stainless steel

Stainless steel multi layer / rubber

20Cr13

graphite

-

Nickel chromium cast iron

Nickel chromium cast iron + stainless steel

rubber

316L

graphite

Other special materials, our company can also be tailored to customer needs.

-

Main performance characteristics

Shell material

Applicable medium

Hard seal temperature(℃)

soft seal temperature(℃)

Nodular graphite cast iron(Q)

Water, air, oil

≤425

≤80

carbon steel(C type)

Water, air, oil

≤425

≤80

Nickel chromium cast iron

seawater

-

≤80

Nominal pressure PN(MPa)

shell

test pressure(MPa)

seal(liquid)

seal(gas)

0.25

0.375

0.275

0.6

0.6

0.9

0.66

0.6

1.0

1.5

1.1

0.6

1.6

2.4

1.8

0.6

Special parameter

Valve opening time (SEC)

Valve diameter

Adjustable

<1000

≥1000

10~60

30~120

Valve angle (degree)

Quick closing

65±10

slow closing

25±10

Valve time (degree)

Quick closing

2~25

3~30

slow closing

4~60

5~60

- Implementation standards

Design specification: JB/T 5299, JB/T 8527

Structure length: GB/T 12221

Connecting flange: GB/T 17241.6, 7005-2 BS, PrEN1092-2 ISO

Experiment and test: GB/T13927, JB/T 9092

Pressure temperature: GB/T 9131

Product identification: GB/T 12220

- Storage and maintenance

Products for a long time, should be placed in a dry place, closed at both ends of the import and export, in the sealing surface coated with anti rust oil. When the temporary parking can be added in the external wall plate auxiliary support to maintain a smooth. The first half is not installed, the hydraulic system for cleaning oil. This valve is prohibited open storage.

Installation and maintenance

Before installation should check the valve nameplate parameter meets the use requirements; cleaning the channel of the valve body and disc, check each part have no damage phenomenon and parts of the bolt is fastened. If the valve is installed in the outlet of the pump, the direction of the valve body to seal the direction of the pressure, and the direction of the water pump in the opposite direction; butterfly valve installed on the basis of the level should be corrected to ensure that the valve shaft does not tilt. Valve supporting feet and auxiliary support is mainly used to ensure the valve installation smooth operation, not a lot of bear perpendicular to the pipe axial water thrust; lifting may not flip, upside down; pay attention to the four lifting points to select the position of equilibrium.

More Products