Product description

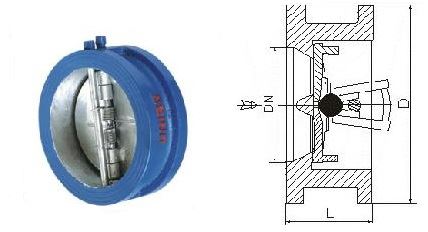

H76 type stop return valve of dual valve structure with two spring loaded valve (valve), hanging in the hinge pin in the vertical center. When the fluid begins to flow, the valve is opened under the action of the center of the sealing surface (F). The action point of the spring supporting force (Fs) of the anti action is located outside the center of the valve flap, so that the root of the valve is opened first. Thus effectively avoid the old conventional valve in the valve open when the sealing surface friction phenomenon.

When the flow rate is slow, the reverse spring is automatically reversed, so that the valve flap is closed, the valve seat is close to the valve seat, and the distance and time of the closing of the valve is reduced. When the fluid flow back, the valve is gradually close to the valve seat, the valve's dynamic response will be greatly accelerated. This dramatically reduces the impact of water hammer phenomenon, so as to achieve no impact performance. When closing, the action of the spring force action point causes the top of the valve flap to be closed first. This prevents the valve from the root of the phenomenon of wear, so that the valve can be maintained for a longer time the integrity of the seal.

Main dimensions and weight(H76 type)

Nominal pressure

1.0

1.6

2.5

4.0

Nominal diameter

size

weight

size

weight

size

weight

size

weight

L

D

L

D

L

D

L

D

50

60

109

1.8

60

109

1.8

60

109

2

60

109

2.4

65

67

129

2.6

67

129

2.6

67

129

3.2

-

-

-

Material code

valve

valve clack

valve stem

Spring

C

WCB carbon steel

20Cr13

20Cr13

304

P

CF8(304) stainless steel

304

304

304

R

CF8M(316)stainless steel

316

316

316

PL

CF3(304L) stainless steel

304L

304

304L

RL

CF3M(316L)stainless steel

316L

316

316L

Other special materials, our company can also be tailored to customer needs.

Shell material

Applicable medium

Applicable temperature(℃)

Carbon steel(C type)

Water, steam, oil

≤425

Chromium nickel titanium(P type)

Nitric acid

≤200

Cr.ni.mo.ti steel(R type)

Acetic acid

≤200

Nominal pressure PN(MPa)

Shell(MPa)

Test pressure(MPa)

Seal (liquid)(MPa)

Seal (gas)(MPa)

1.0

1.5

1.1

0.6

1.6

2.4

1.8

0.6

2.5

3.8

2.8

0.6

4.0

6.0

4.4

0.6

Implementation standards:

Design standard: CB/T4303

Structure length: GB/T12221

Experiment and test: JB/T9092, GB/T13927

Pressure - temperature: GB/T9131

Product label: GB/T12220

- Storage and maintenance

1 the valve must be kept in a dry, ventilated room.

2 during the storage of the valve, the valve should be closed and fixed.

3 during the storage of the valve, the surface of the machine is easy to be removed.

4 long-term storage of the valve should be regularly checked, timely protection.

Installation and maintenance

1 this valve is installed in any direction.

2 must be carefully checked before installation, the valve plate is marked and consistent with the requirement and condition.

3 when installing, should check the inner cavity, remove the valve flap fixing device, try to check the sealing surface of the valve flap, and clean.

4.. Lifting the valve before, should check whether it has been tightening screw ring.

5 installation should pay special attention to media flow, should make the normal flow direction of the media and the direction of the arrow on the valve body consistent.

6 when installing, tighten the connecting bolts evenly and symmetrically.

More Products