The product description

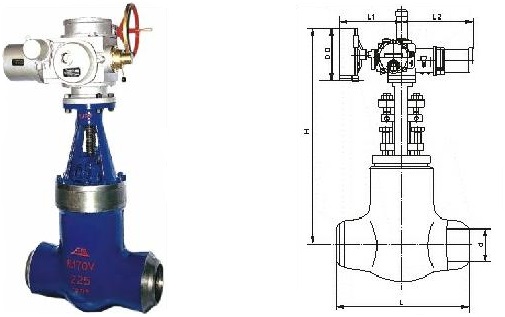

Special high temperature and high pressure power station gate "also known as power station valve, the pipeline is mainly used in the thermal power plant all kinds of system, cut off or connect pipe medium. Applicable medium: water, steam and other corrosive medium. Power station valve compared with other valve products is characterized by high temperature and high pressure, the unique since the seal design, the higher the pressure, the more reliable seal. Because of performance technology characteristics, operating mode of the special products have formed the characteristics do not replace the other products. This kind of valve shall generally be installed in the pipeline.

The main dimensions and weight 1500Lb

Nominal diameter

Main shapes and connection size(mm)

Electric actuator

d

L

H

H0

L1

L2

2-1/2"

56

254

520

200

140

243

SMC-04

3"

64

305

523

200

140

243

SMC-04

4"

85

406

599

508

198

281

SMC-03

599

305

400

555

SMC-00

5"

100

483

678

508

198

281

SMC-03

678

305

400

555

SMC-00

6"

126

559

793

305

410

565

SMC-0

793

305

420

654

SMC-1

8"

158

711

813

305

410

565

SMC-0

813

305

420

654

SMC-1

10"

200

864

998

457

440

688

SMC-2

988

305

420

654

SMC-1

12"

250

991

1141

305

420

654

SMC-1

1156

457

440

688

SMC-2

The main dimensions and weight 2000Lb

Nominal diameter

Main shapes and connection size(mm)

Electric actuator

d

L

H

H0

L1

L2

2-1/2"

50

330

540

200

140

243

SMC-04

3"

60

368

558

508

198

332

SMC-03

4"

80

457

654

305

400

555

SMC-00

5"

96

533

780

305

400

555

SMC-00

780

305

410

565

SMC-0

6"

118

610

830

305

410

565

SMC-0

8"

148

762

960

305

410

565

SMC-0

960

305

420

654

SMC-1

10"

180

914

1020

304

420

654

SMC-1

1024

457

440

688

SMC-2

12"

222

1041

1150

457

440

688

SMC-2

14"

254

1118

1230

457

440

688

SMC-2

The main dimensions and weight 2500Lb

Nominal diameter

Main shapes and connection size(mm)

Electric actuator

d

L

H

H0

L1

L2

2-1/2"

46

330

533

508

198

332

SMC-03

533

200

140

243

SMC-04

3"

54

368

549

508

198

332

SMC-03

549

200

140

243

SMC-04

4"

70

457

653

508

198

332

SMC-03

644

305

410

565

SMC-0

5"

86

533

760

305

400

555

SMC-00

774

305

400

565

SMC-0

6"

104

610

850

305

400

555

SMC-00

861

305

410

565

SMC-0

8"

130

762

847

305

410

565

SMC-0

860

305

420

654

SMC-1

10"

162

914

1021

305

420

654

SMC-1

The main dimensions and weight 3500Lb

Nominal diameter

Main shapes and connection size(mm)

Electric actuator

d

L

H

H0

L1

L2

3"

44

440

620

508

198

332

SMC-03

623

305

400

555

SMC-00

4"

56

540

721

305

400

555

SMC-00

730

305

410

565

SMC-0

5"

74

616

796

305

410

565

SMC-0

796

305

420

654

SMC-1

6"

88

692

857

305

410

565

SMC-0

857

305

420

654

SMC-1

8"

116

846

1041

305

420

654

SMC-1

1051

457

440

688

SMC-2

10"

142

1000

1197

457

440

688

SMC-2

The major parts material

Valve body, valve cover, gate

The stem

Stem and nut

filler

handwheel

C

ASTM A216 WCB carbon steel

20Cr13

ZQAL9-4

graphite

malleable iron

P

ASTM A351 CF8(304) stainless steel

ASTM A182 F304

ZQAL9-4

PTFE

malleable iron

R

ASTM A351 CF8M(316) stainless steel

ASTM A182 F316

ZQAL9-4

PTFE

malleable iron

I

ASTM A217 WC6 Cr Mo steel

38CrMoAL

ZQAL9-4

graphite

malleable iron

V

ASTM A217 WC9 Cr Mo steel

25Cr2MoVA

ZQAL9-4

graphite

malleable iron

Other special materials, our company can also be tailored to customer needs.

The performance specification

shell material

applicable medium

applicable temperature(℃)

Carbon steel(C type)

Water, steam, oil

≤425

Chromium nickel titanium steel(P type)

Nitrate class

≤200

Titanium nickel chrome molybdenum steel(R type)

Acetic acid class

≤200

Chrome molybdenum steel(I、V type)

Water, steam, oil

≤550

Nominal pressure(Lb)

shell(MPa)

Test pressure(MPa)

upper seal(MPa)

seal(liquid)(MPa)

seal(gas)(MPa)

1500

37.5

27.5

0.6

27.5

2000

54

39.6

0.6

39.6

2500

63

46.2

0.6

46.2

- Implementation standards:

Design standard: B16.34 API ASME 600 E101

Structure length: B16.10 E101 ASME

Groove size: ASME B16.25

Experiment and test: API 598

Pressure - temperature: B16.34 ASME

Product label: B16.34 ASME

- Storage and maintenance

Valves can be stored in any area of the mask, but must pay attention to prevent the valve is soil or ground dirty. At the time of shipment, the inlet and outlet of the valve are provided with a protective cover. Note that before the installation of the valve, do not remove these protective cover. When the valve is ready to be installed, the protective end cover is removed first, and then the connection parts are cleaned. If is the butt welding end of the valve, to remove all visible foreign body. Use suitable solution to clean the parts that need to be welded, such as acetone or alcohol. Do not use a solution containing fluoride or chloride.

Installation and maintenance

1 handwheel, handle and drive mechanism for lifting are not allowed to use, and avoid collision.

2 double gate valve should be installed vertically (that is, the valve stem is in the vertical position, the hand wheel at the top).

3 valve with bypass valve should be opened before opening the bypass valve (in order to balance the pressure of the inlet and outlet and reduce the opening force).

4 with the transmission mechanism of the gate valve, according to the provisions of the product manual installation.

5 if the valve is often used to switch, at least once a month.

More Products