Product description

The electric ball valve is provided with the same rotating 90 degree lifting action, with a circular through hole or a channel through its axis. The ratio of the spherical surface and the channel port should be such that when the ball is rotated 90 degrees, the inlet and outlet should be all spherical, thereby cutting off the flow. Electric ball valves only need a very small torque can be closed tight. Full equality of the inner cavity of the valve body to provide a very small resistance, through the flow channel. It is generally considered the most suitable for direct use, but the recent development has been designed so that it has a throttle and control flow. Electric ball valve is now in the oil, natural gas, medicine, food, water and electricity, nuclear power, electricity, water supply and drainage, heating, metallurgy and other industries to be widely used, is the key to the construction of national defense machinery products. It occupies a lot in the market share, mainly because the electric ball valve strong function, small volume, reliable performance, flow capacity, light and pleasant, remote control, such as a variety of reasons, electric ball valve is not only throttle, cut-off, cutting, breaking, good products or flow regulating system of preferred products.

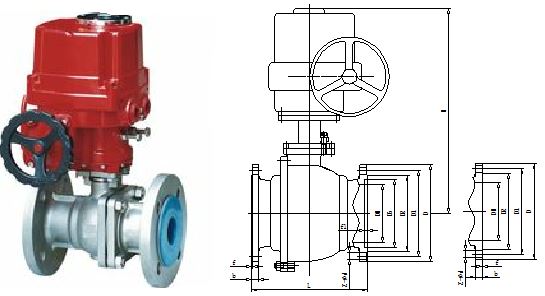

Main connection and dimensions(PN16)

nominal diameter

Main valve connection dimensions

Valve connection size

Flange connection size

L

H

D

D1

D2

b

f

Z-Φd

25

150

360

115

85

65

14

2

4-Φ14

32

165

390

135

100

78

16

2

4-Φ18

40

180

395

145

110

85

16

3

4-Φ18

50

200

405

160

125

100

16

3

4-Φ18

65

220

490

180

145

120

18

3

4-Φ18

80

250

595

195

160

135

20

3

8-Φ18

100

280

640

215

180

155

20

3

8-Φ18

125

320

695

245

210

185

22

3

8-Φ18

150

360

740

280

240

210

24

3

8-Φ23

200

400

800

335

295

265

26

3

12-Φ23

250

550

880

405

355

320

30

3

12-Φ25

Main connection and dimensions(PN25)

nominal diameter

Main valve connection dimensions

Valve connection size

flange connection size

L

H

D

D1

D2

b

f

Z-Φd

25

150

360

115

85

65

16

2

4-Φ14

32

165

390

135

100

78

18

2

4-Φ18

40

180

395

145

110

85

18

3

4-Φ18

50

200

405

160

125

100

20

3

4-Φ18

65

220

490

180

145

120

22

3

8-Φ18

80

250

595

195

160

135

22

3

8-Φ18

100

280

640

230

190

160

24

3

8-Φ23

125

320

695

270

220

188

28

3

8-Φ25

150

360

740

300

250

218

30

3

8-Φ25

200

400

800

360

310

278

34

3

12-Φ25

250

550

880

425

370

332

36

3

12-Φ30

Main connection and dimensions(PN40)

nominal diameter

Main valve connection dimensions

Valve connection size

flange connection size

L

H

D

D1

D2

D6

b

f

f2

z-Φd

25

150

360

115

85

65

58

16

2

4

4-Φ14

32

180

390

135

100

78

66

18

2

4

4-Φ18

40

200

395

145

110

85

76

18

3

4

4-Φ18

50

220

405

160

125

100

88

20

3

4

4-Φ18

65

250

490

180

145

120

110

22

3

4

8-Φ18

80

280

595

195

160

135

121

22

3

4

8-Φ18

100

320

640

230

190

160

150

24

3

4

8-Φ23

125

400

695

270

220

188

176

28

3

4.5

8-Φ25

150

400

740

300

250

218

204

30

3

4.5

8-Φ25

200

550

800

375

320

282

260

38

3

4.5

12-Φ30

Main connection and dimensions(PN64)

nominal diameter

Main valve connection dimensions

Valve connection size

Flange connection size

L

H

D

D1

D2

D6

b

f

f2

z-Φd

25

216

360

135

100

78

58

22

2

4

4-Φ18

32

229

390

150

110

82

66

24

2

4

4-Φ23

40

241

395

165

125

95

76

24

3

4

4-Φ23

50

292

405

175

135

105

88

26

3

4

4-Φ23

65

330

490

200

160

130

110

28

3

4

8-Φ23

80

356

595

210

170

140

121

30

3

4

8-Φ23

100

432

640

250

200

168

150

32

3

4.5

8-Φ25

125

508

695

295

240

202

176

36

3

4.5

8-Φ30

150

559

740

340

280

240

204

38

3

4.5

8-Φ34

200

660

800

405

345

300

260

44

3

4.5

12-Φ34

Main parts material

Soft seal

material code

valve body

ball body

valve stem

sealing ring

filler

shim

C

WCB carbon steel

20Cr13

20Cr13

PTFE/PPL

graphite

304+graphite

P

CF8 (304 )stainless steel

304

304

PTFE/PPL

PTFE/PPL

PTFE/PPL

PL

CF3 (304 L) stainless steel

304L

304L

PTFE/PPL

PTFE/PPL

PTFE/PPL

R

CF8M (316) stainless steel

316

316

PTFE/PPL

PTFE/PPL

PTFE/PPL

RL

CF3M(316L)stainless steel

316L

316L

PTFE/PPL

PTFE/PPL

PTFE/PPL

hard seal

material code

valve body

ball body

valve stem

valve seat filler

shim

C

WCB carbon steel

20Cr13+Nickel based alloy / tungsten cobalt alloy

20Cr13

20Cr13+Cemented carbide

graphite

304+graphite

P

CF8 (304 )stainless steel

304+Nickel based alloy / tungsten cobalt alloy

304

304+Cemented carbide

graphite

304+graphite

PL

CF3 (304 L) stainless steel

304L+Nickel based alloy / tungsten cobalt alloy

304L

304L+Cemented carbide

graphite

304+graphite

R

CF8M (316) stainless steel

316+Nickel based alloy / tungsten cobalt alloy

316

316+Cemented carbide

graphite

304+graphite

RL

CF3M(316L)stainless steel

316L+Nickel based alloy / tungsten cobalt alloy

316L

316L+Cemented carbide

graphite

304+graphite

Other special materials, our company can also be tailored to customer needs.

Shell material

Applicable medium

Applicable temperature(℃)

remarks

WCB(C type)

Water, steam, oil

≤150

When the sealing ring for PPL

≤280℃

CF8(P type)

Nitric acid

≤150

CF8M(R type)

Acetic acid

≤150

CF3(PL type )

Strong oxidizing medium

≤150

CF3M(RL type)

Urea and other corrosive media

≤150

Shell material

Applicable medium

Applicable temperature(℃)

WCB(C type)

Water, steam, oil

≤425

CF8(P type)

Nitric acid

≤540

CF8M(R type)

Acetic acid

≤540

CF3(PL type)

Strong oxidizing medium

≤425

CF3M(RL type)

Urea and other corrosive media

≤425

nominal diameter PN(MPa)

shell(MPa)

test pressure(MPa)

sealing(liquid)(MPa)

sealing(gas)(MPa)

1.6

2.4

1.8

0.6

2.5

3.8

2.8

0.6

4

6

4.4

0.6

6.4

9.6

7

0.6

- Implementation standards

Design specification: GB/T 12237

Structure length: GB/T 12221

Connecting flange: GB/T9113, HG/T20592, HG/T20615, JB/T 79

Experiment and test: GB/T13927, JB/T 9092

Pressure temperature: GB/T 9131

Product identification: GB/T 12220

- Storage and maintenance:

1 valves should be stored in a dry and ventilated place. The application of lid port channel.

2 long-term storage of the valve should be regularly checked and cleaned, in particular, to clean the surface of the valve seat sealing surface to prevent damage.

3 if stored for more than 18 months, the valve should be tested before installation, and make a good record.

4 electric valve repair and assembly, the sealing performance test should be carried out.

Installation and maintenance:

1 before installation to confirm the valve identification (such as models, nominal diameter, nominal pressure, material) is based on the requirements of the pipeline system identification.

2 carefully check the valve's channel and sealing surface before installation. If you have any goods, shall be cleaned.

3 before installation, make sure that all the bolts are tightened.

4 before installation, make sure the packing is pressed.

More Products