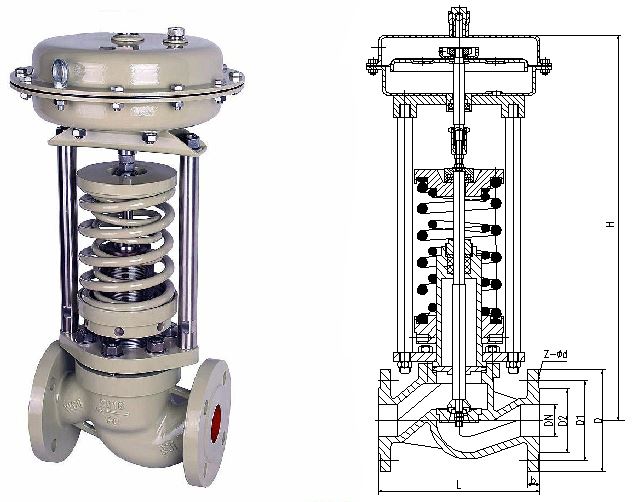

Product description

ZZYP self regulating valve is a kind of without external driving energy, by adjusting the pressure of the medium itself as the power source and the medium pressure changes, according to the predetermined set values, automatic adjustment of the energy saving control device. It sets the detection, control, perform many functions in a valve, self-contained instrument control system.

Main connection and outline dimensions(PN16)

Nominal diameter

Main dimensions and connection dimensions

valve size

flange connection size

L

H

D

D1

D2

b

f

z-Φd

20

150

475

105

75

56

18

2

4-Φ14

25

160

475

115

85

65

18

2

4-Φ14

32

180

520

140

100

76

18

2

4-Φ18

40

200

520

150

110

84

18

3

4-Φ18

50

230

540

165

125

99

18

3

4-Φ18

65

290

710

185

145

118

18

3

4-Φ18

80

310

780

200

160

132

20

3

8-Φ18

100

350

780

220

180

156

20

3

8-Φ18

125

400

840

250

210

184

22

3

8-Φ18

150

480

880

285

240

211

22

3

8-Φ22

200

600

915

340

295

266

24

3

12-Φ22

-

Main parts material

Material code

Valve body, valve cover

valve stem

valve seat

spool

filler

shim

C

WCB carbon steel

20Cr13

304

304

graphite

304+graphite

P

CF8 stainless steel

304

304

304

PTFE

PTFE

R

CF8M stainless steel

316

316

316

PTFE

PTFE

PL

CF3 stainless steel

304L

304L

304L

PTFE

PTFE

RL

CF3M stainless steel

316L

316L

316L

PTFE

PTFE

Other special materials, our company can also be tailored to customer needs.

-

Main performance characteristics

Shell material

Applicable medium

Applicable temperature(℃)

WCB(C type)

Water, steam, oil

≤425

CF8(P type)

Nitric acid

≤150

CF8M(R type)

Nitric acid

≤150

Nominal pressure PN(MPa)

shell(MPa)

Test pressure(MPa)

Upper seal(MPa)

Seal (liquid)(MPa)

Seal (gas)(MPa)

1.0

1.5

1.1

0.6

1.1

1.6

2.4

1.76

0.6

1.76

2.5

3.75

2.75

0.6

2.75

- Implementation standards

Design specification: GB/T4213 GB/T17213

Structure length: GB/T12221

Connecting flange: GB/T9113, HG/T20592, HG/T20615, JB/T 79

Experiment and test: GB/T13927, JB/T 9092

Pressure temperature: GB/T 9131

Product identification: GB/T 12220

- Valve maintenance

1 before installation should be carefully check valve nameplate content, to ensure that the valve type, size, seat materials, temperature rated values in line with the use of pipeline.

2 remove the protective cover on both sides of the flange, the valve is fully open in the state to wash clean.

3 prepare and remove the remaining impurities in the clean piping (which may damage the valve seat and ball) before connecting the pipe to the pipe.

4 during the installation, please do not use the valve body part as a lifting point, to avoid damage to the actuator and accessories. .

5 this type of valve should be installed in the horizontal direction or vertical direction of the pipe.

6. Install the pipeline near the falls, or to withstand external force phenomenon, can use pipe support or supports pipeline to eliminate the deviation.

7 after connecting with the pipe, use the specified torque cross locking flange connection bolt.

More Products