The product description

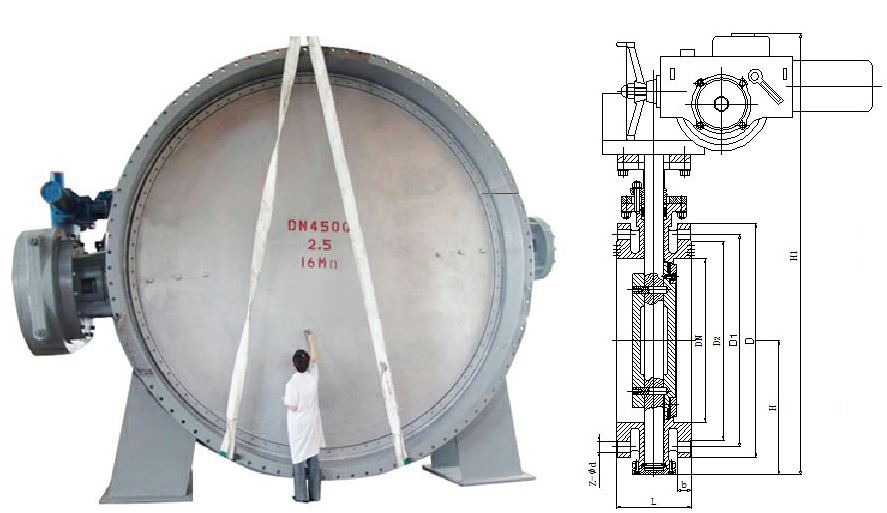

D943 type electric butterfly valve is through the circular disc plate with the valve rod rotation as open-close, open or close the valve, butterfly valve is mainly for the use of block valves, can also be designed to have the function of regulating and truncation. Valves electric actuator save a lot of manpower and opening closing time. Triple eccentric multi-level butterfly valve has no mechanical wear and tear, can reach zero leakage, suitable for petroleum, chemical industry, metallurgy, electric power, food, medicine, on different medium such as water supply and drainage, gas transmission pipeline as the adjusting and the best device to cutting fluid.

The main connection and overall dimensions(PN10)

norminal diameter

main overal size and connection size(mm)

valve size mm

flange connection size mm

L

H

H1

D

D1

D2

b

f

z-Φd

short series

long series

50

108

150

112

530

165

125

93

18

3

4-Φ18

65

112

170

115

530

185

145

113

18

3

4-Φ18

80

114

180

120

565

200

160

128

20

3

8-Φ18

100

127

190

138

600

220

180

148

20

3

8-Φ18

125

140

200

164

640

250

210

178

22

3

8-Φ18

150

140

210

175

705

285

240

204

22

3

8-Φ22

200

152

230

200

775

340

295

259

24

3

8-Φ22

250

165

250

243

945

395

350

314

26

3

12-Φ22

300

178

270

283

1070

445

400

362

26

4

12-Φ22

350

190

290

310

1140

505

460

422

26

4

16-Φ22

400

216

310

340

1210

565

515

473

26

4

16-Φ26

450

222

330

380

1335

615

565

523

28

4

20-Φ26

500

229

350

410

1415

670

620

578

28

4

20-Φ26

600

267

390

470

1605

780

725

677

34

5

20-Φ30

700

292

430

550

1844

895

840

792

35

5

24-Φ30

800

318

470

640

2040

1015

950

899

38

5

24-Φ33

900

330

510

710

2255

1115

1050

999

38

5

28-Φ33

1000

410

550

770

2380

1230

1160

1106

44

5

28-Φ36

1200

470

630

890

2640

1455

1380

1323

55

5

32-Φ39

main connection and overal sizes(PN16)

norminal diameter

main overal size and connection size(mm)

valve sizes mm

flange connection sizes mm

L

H

H1

D

D1

D2

b

f

z-Φd

short series

long series

50

108

150

112

530

165

125

93

18

3

4-Φ18

65

112

170

115

530

185

145

113

18

3

4-Φ18

80

114

180

120

565

200

160

128

20

3

8-Φ18

100

127

190

138

600

220

180

148

20

3

8-Φ18

125

140

200

164

640

250

210

178

22

3

8-Φ18

150

140

210

175

705

285

240

204

22

3

8-Φ22

200

152

230

200

775

340

295

259

24

3

12-Φ22

250

165

250

243

945

405

355

315

26

3

12-Φ26

300

178

270

283

1070

460

410

370

28

3

12-Φ26

350

190

290

310

1140

520

470

428

30

4

16-Φ26

400

216

310

340

1210

580

525

479

32

4

16-Φ30

450

222

330

380

1335

640

585

539

40

4

20-Φ30

500

229

350

410

1415

715

650

601

44

4

20-Φ33

600

267

390

470

1605

840

770

716

54

5

20-Φ36

700

292

430

550

1844

910

840

786

58

5

24-Φ36

800

318

470

640

2040

1025

950

893

62

5

24-Φ39

900

330

510

710

2255

1125

1050

993

64

5

28-Φ39

1000

410

550

770

2380

1255

1170

1110

68

5

28-Φ42

1200

470

630

890

2640

1485

1390

1324

78

5

32-Φ48

main connection and overal sizes(PN25)

norminal diameter

main overal sizes and connection (mm)

valve sizes mm

flange connection sizes mm

L

H

H1

D

D1

D2

b

f

z-Φd

short series

long series

50

108

150

112

530

165

125

93

20

3

4-Φ18

65

112

170

115

530

185

145

113

22

3

8-Φ18

80

114

180

120

565

200

160

128

24

3

8-Φ18

100

127

190

138

600

235

190

154

24

3

8-Φ22

125

140

200

164

640

270

220

180

26

3

8-Φ26

150

140

210

175

705

300

250

210

28

3

8-Φ26

200

152

230

200

775

360

310

270

30

3

12-Φ26

250

165

250

243

945

425

370

326

32

3

12-Φ30

300

178

270

283

1070

485

430

386

34

3

16-Φ30

350

190

290

310

1140

555

490

441

38

4

16-Φ33

400

216

310

340

1210

620

550

498

40

4

16-Φ36

450

222

330

380

1335

670

600

548

46

4

20-Φ36

500

229

350

410

1415

730

660

608

48

4

20-Φ36

600

267

390

470

1605

845

770

713

58

5

20-Φ39

700

292

430

550

1844

960

875

815

60

5

24-Φ42

800

318

470

640

2040

1085

990

924

66

5

24-Φ48

900

330

510

710

2255

1185

1090

1024

70

5

28-Φ48

1000

410

550

770

2380

1320

1210

1136

74

5

28-Φ56

1200

470

630

890

2640

1530

1420

1346

86

5

32-Φ56

The major parts material

material code

Body and bonnet

Valve plate

valve seat

Sealing ring

The valve stem

packing

z

HT200 gray cast iron

gray cast iron

HT200+ copper/stainless steel

Stainless steel multi-layer

20Cr13

graphite

Q

QT450 nodular cast iron

nodular cast iron

QT450+ copper/stainless steel

Stainless steel multi-layer

20Cr13

graphite

C

WCB steel

steel

WCB+copper/stainless steel/carbide

Stainless steel multi-layer

20Cr13

graphite

P

CF8 (304 )Stainless steel

Stainless steel

Stainless steel

Stainless steel multi-layer

304

PTFE

R

CF8M (316) Stainless steel

Stainless steel

Stainless steel

Stainless steel multi-layer

316

PTFE

PL

CF3 (304 L)Stainless steel

Stainless steel

Stainless steel

Stainless steel multi-layer

304L

PTFE

RL

CF3M (316L) Stainless steel

Stainless steel

Stainless steel

Stainless steel multi-layer

316L

PTFE

Other special material our company can also be customized according to customer's requirements.

The main performance characteristics

Shell material

Applicable medium

Suitable temperature(℃)

Gray cast iron(Z)

Water, air, oil

≤200

Nodular cast iron(Q)

Water, air, oil

≤350

Carbon steel(C type)

Water, air, oil

≤425

Chromium nickel titanium steel(P type)

Nitrate class

≤150

Titanium nickel chrome molybdenum steel(R type)

Nitrate class

≤150

Nominal pressure PN(MPa)

shell

Test pressure(MPa)

Seal (liquid)

Seal (gas)

0.6

0.9

0.66

0.6

1.0

1.5

1.1

0.6

1.6

2.4

1.8

0.6

2.5

3.8

2.8

0.6

4

6

4.4

0.6

- $Column4$

- $Column5$

More Products